3D printing is possible thanks to light or heat. Now there is a third option – audio.

Most current 3D printing methods rely on light or heat activation reactions to produce objects with precise shapes. A technology called direct sonic printing (DSP) could completely revolutionize not only the 3D printing industry, but the industry as a whole. Developed by scientists from Concordia University describe in Nature Communications.

Ultrasound frequencies are already used in destructive procedures such as laser resections of tissues and tumors. We wanted to use it to create something.

the professor. Muthukumaran from Packirisamy’s from Concordia University

It turns out that focused ultrasound can be used to induce acoustic chemical reactions in cavitation regions of small dimensions – simply put: in microscopic air bubbles. Due to the extreme temperature and pressure values, it is possible to create pre-designed geometries that cannot be produced using other techniques.

We found that if we use a certain type of ultrasound with a certain frequency and strength, we can create highly focused regions of chemical reactions. In general, bubbles can be used as reactors to trigger chemical reactions that turn liquid resin into solid or semi-solid materials.

Mohsen Habibi from Concordia University

Tests have shown that responses caused by ultrasound-guided oscillations are intense, although they only last a few seconds. The temperature inside the bubbles rises to about 15,000 K and the pressure exceeds 1,000 bar.

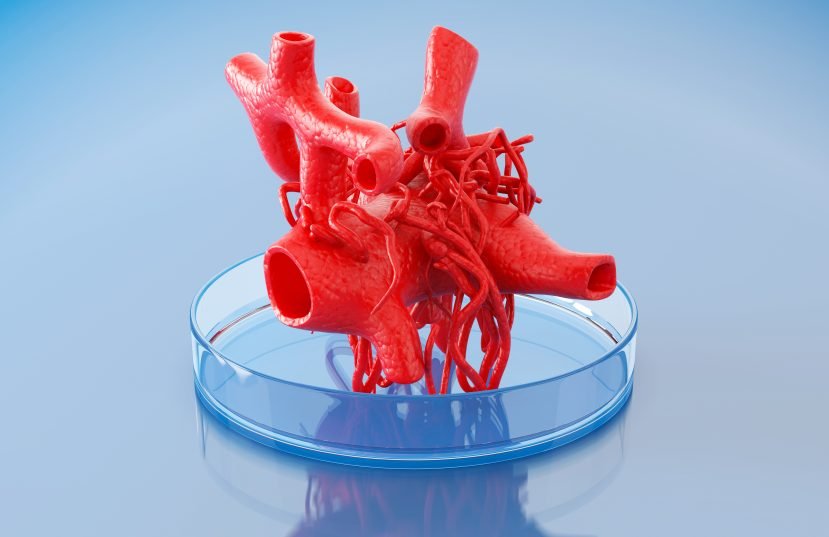

Scientists conducted experiments with a polymer used in the production of additives, called polydimethylsiloxane (PDMS). The new technology may be useful in industries where complex and sensitive devices are used. PDMS polymers are used in the microfluidic industry and to create biosensors. Aviation should also take advantage of DSP capabilities.

We’ve demonstrated that we can print from many materials, including polymers and ceramics. Next, we are going to experiment with metal-polymer compounds, and eventually we want to print the metal in this way.

the professor. Muthukumaran Bakirsama

Echo Richards embodies a personality that is a delightful contradiction: a humble musicaholic who never brags about her expansive knowledge of both classic and contemporary tunes. Infuriatingly modest, one would never know from a mere conversation how deeply entrenched she is in the world of music. This passion seamlessly translates into her problem-solving skills, with Echo often drawing inspiration from melodies and rhythms. A voracious reader, she dives deep into literature, using stories to influence her own hardcore writing. Her spirited advocacy for alcohol isn’t about mere indulgence, but about celebrating life’s poignant moments.